- Welcome to Balaji Marketing

COPPER TUNSTEN PARTS

Copper Tungsten Parts

- The Superiority of Copper Tungsten Alloys

- Tailored Solutions for Varied Industries

- Precision Machining Techniques

- Sustainable Manufacturing Practices

- Collaborative Innovation and Research

- copper tungsten parts manufacturers stand as architects of innovation.

Copper Tungsten Parts

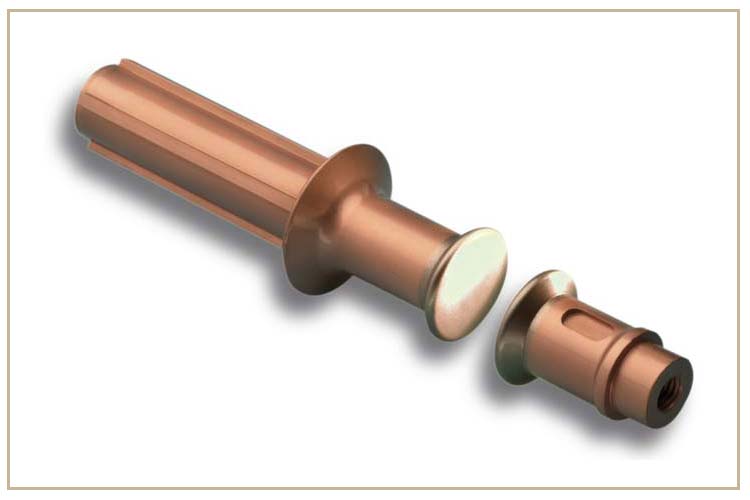

As industries advance, the need for high-performance materials is increasing rapidly. Copper tungsten emerges as a standout alloy in this context, known for its exceptional electrical conductivity, thermal stability, and mechanical strength. In the realm of precision engineering, copper tungsten parts manufacturers are crucial in providing advanced solutions that foster innovation across various industries.

The Superiority of Copper Tungsten Alloys

Copper tungsten alloys, which consist of copper and tungsten in various proportions, offer outstanding properties that make them essential in the manufacturing industry. These alloys are known for their high thermal conductivity, low thermal expansion, and excellent wear resistance, making them perfect for use in challenging environments. Copper tungsten parts, produced by specialized Copper Tungsten Parts Manufacturers, excel in aerospace, electronics, and automotive sectors due to their ability to endure extreme conditions while maintaining optimal performance.

Tailored Solutions for Varied Industries

Copper tungsten parts manufacturers recognize the varied demands of contemporary industries. Whether it's producing electrical contacts for circuit breakers or crafting rocket nozzles for aerospace applications, these manufacturers excel in customizing copper tungsten components to fit the unique needs of each sector. The versatility of copper tungsten makes it an ideal choice for industries that prioritize reliability, durability, and high performance.

Precision Machining Techniques

To attain the optimal properties in copper tungsten parts, expertise in precision machining techniques is crucial. Copper tungsten parts manufacturers utilize advanced machining technologies, including CNC milling and EDM (Electrical Discharge Machining), to produce intricate and complex shapes with the highest level of accuracy. This precision is vital for adhering to the strict tolerances required by industries that depend on copper tungsten components.

Sustainable Manufacturing Practices

As global attention on sustainability sharpens, copper tungsten parts manufacturers are adopting eco-friendly practices. The durability and recyclability of this alloy support a more sustainable manufacturing process. By integrating responsible sourcing and recycling initiatives, these manufacturers are in step with the increasing environmental awareness in the industrial sector.

Collaborative Innovation and Research

The quest for excellence is ongoing, with copper tungsten parts manufacturers at the forefront of collaborative research and development efforts. By teaming up with research institutions and industry experts, these manufacturers are constantly advancing the capabilities of copper tungsten alloys. This dedication to innovation guarantees that clients benefit from cutting-edge solutions that meet the latest industry standards.

copper tungsten parts manufacturers stand as architects of innovation.

In the field of advanced materials, copper tungsten parts manufacturers are at the forefront of innovation. Leveraging their expertise and the exceptional characteristics of copper tungsten alloys, these manufacturers deliver customized solutions that help industries achieve unprecedented levels of performance. As technology evolves, the influence of copper tungsten parts manufacturers in shaping the future of manufacturing becomes increasingly crucial, driving advancement and expanding the possibilities of copper tungsten applications.